We are leading exporters of griege & dyed fabric

INFRASTRUCTURE

HIGH-TECH INFRASTRUCTURE

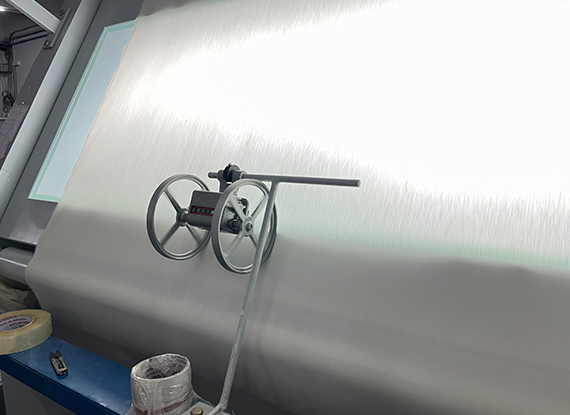

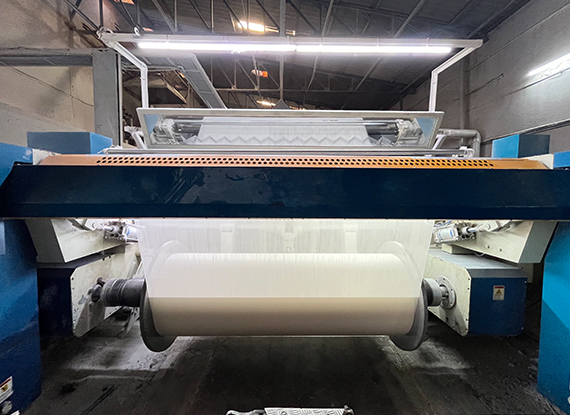

Over 60,000 square feet of digitally controlled humidification plants and fogging systems allow the business to weave different fibres and densities to match market demands. We have a thorough research and development infrastructure to ensure proper testing and quality. This cutting-edge infrastructure supports all design and development stages. Our manufacturing unit has the infrastructure to meet the needs of our clients, globally and domestic level. Our factory showcases our state-of-the-art machinery and techniques that guarantee the production of superior greige fabric for export.

We have more than 42 pieces of Toyota JAT810 equipment with 8-16 shafts, 2-4 feeders and speed of 1100 RPM. These tools have a wide variety of unique Toyota components, such as the energy-saving Air-Saving System and the innovative "E-shed" electronic shedding motion. In addition, the ease of use has been greatly enhanced by the installation of a function panel and a factory management system.

We have more than 42 pieces of Toyota JAT810 equipment with 8-16 shafts, 2-4 feeders and speed of 1100 RPM. These tools have a wide variety of unique Toyota components, such as the energy-saving Air-Saving System and the innovative "E-shed" electronic shedding motion. In addition, the ease of use has been greatly enhanced by the installation of a function panel and a factory management system.